Atibal Vantage 2000: WMLRF Equipped with OLED Display

Atibal Optics has released the Vantage 2000, the first OLED-equipped weapon-mounted ballistic laser…

Atibal Optics has released the Vantage 2000, the first OLED-equipped weapon-mounted ballistic laser…

If you’re a reader of UN12 or regular visitor to this website, you…

In a world where shooters can’t get enough of 2011-style pistols, SIG introduced…

All shooting is a balance between speed and precision. By that I mean you can…

The Mod-Navy Qual I’ve been doing this qual (or drill, or whatever the current nom…

• Built for road trips and off-road use• Manual transmission equipped• Wrapped in MultiCam Arctic…

From Hydro Dip to assembly and on to the range, Jody Lewis takes an everyday AR on an adventure of customization.

Recently my good friend over at Cross Machine & Tool (CMT) wanted to make a big splash with their new Billet Upper AR-15 receiver, so they sent me some in the white (unfinished) to be photographed. After taking some photos, I decided it would be a shame to leave the upper raw, so I decided to embark on a custom build.

Up until this project, I had never had a gun hydro dipped and really did not know much about it other than it looked good. Enter Joint Force Enterprises (JFE). I told them I was doing a custom build for photos, so they agreed to hook me up with a killer deal. I sent the upper, lower, rail and stock Priority mail to their shop in Jacksonville Florida. I am not sure if it was because they gave me special pricing or the fact they were in the middle of a major move or it could just be normal turn around because they are super popular, but the 4 parts took right around 6 months to get back, which I thought was a little long, but because it was a fun project, I did not mind waiting.

As you can see from the photos, the hydro looks great in photos, but in person, you can definitely see some of the drawbacks to hydro dipping. The first thing I noticed was a white basecoat applied that I assume is to aid in adhering the dip. It stands out like a sore thumb wherever Hydro Dip does not go. Another drawback I found once I got everything back is that because the Hydro is generally not hard, they must coat it with clear coat to protect it, which in-turn creates very tight tolerances in the little areas such as detents, etc. Even with clear coat, the dip is somewhat fragile, not like Duracoat but it is thin and will scratch easily.

Although JFE offers Cerakote, I didn’t want to send them all the little parts, so I decided to find a local Cerakote shop here in the Northwest I could have coat the majority of the other parts. I packed everything into a box and shipped it to the guys at MAD Custom Coating in Paulsbo, WA. I didn’t know what color I wanted to ascent the Hydro, but I trusted they would. I told them that I was pairing the parts with a multicam gun and to pick whatever they thought would go with it best.

I was completely expecting they would take a couple of months since that seems the norm these days, but after two weeks, I got the call the parts were done. I figured they must not be very busy.

Now keep in mind, I sent these guys everything that goes on an AR-15 minus the 4 Hydro Parts. We are talking tiny parts like the setscrews for the BAD lever. I decided to pick everything up in person so I could meet the MAD crew and get a first hand look at their shop.

When I arrived, I was thoroughly surprised by the size of their shop. The entire place was not much bigger than 600 square feet. I am not sure how they crammed a spray room, oven room and the armory where they re-assemble guns into such a small building, but they did. They were kind enough to give me the tour and show me around the shop, which took forever due to the size ?. In all seriousness, they were all kinds of busy with tons of work going on. I can only imagine how much spraying they do considering MAD started out doing work for the military.

I was very happy with the color they had chosen which was a dark brown, also known at Patriot Brown. It is darker than Magpul FDE and flat and went very well with the Multicam Kryptek Dip.

So there I am assembling this soon to be masterpiece of color. As someone who has probably built close to 200 ARs since the 2004 ban lifted, I found myself frustrated by some of the new tolerance issues I would have to overcome to complete assembly. A few things such as the safety detent hole had to be reamed and the forward assist pocket sanded. All in all it added an additional half hour to the build but was well worth it.

I choose a Vortex Razor 1-6 simply because of the color scheme, but here is the rest of the build:

Steve Coulston and I took the new rifle out to the range for some photos and the first shot down range we experienced a FTE that required a cleaning rod to remove the spent shell, I cleaned the chamber and added a little FrogLube and all was good from there on out.

The Rainier Arms mountain barrel is simply amazing, being that is an FN barrel made from Machine Gun Steel and Cold Hammer Forged. Average groups at 100 yards off hand were sub-moa coming in right around at .79.

All in all, I love the look and will continue to beat on the finish to see how it wears long term. Much of the chatter I hear from the Cerakote guys is that Hydro Dip doesn’t last, so we will see. After the first 500 rounds it has held up pretty damn well.

Jody has been involved in firearms one way or the other for the past 20+ years. Jody holds multiple professional certifications including the NRA basic firearm instructor and RO training. When he isn’t teaching or training, he writes and photographs regularly for a number of online and print publications. Jody is an NRA Member as well as a certified S&W M&P Armorer as well as a part-time 3-gun competitor. As an Amazon Associate, I earn from qualifying purchases.

[dcs_img_center framed=”no” w=”600″ h=”464″] http://gunsandtactics.wpengine.com/wp-content/uploads/2012/11/FNS-9-full.png [/dcs_img_center] [dcs_post_top] [dcs_fancy_header color=”#000000″ fweight=”bold”]FNH USA, leading manufacturer of high-quality, innovative firearms for military, law enforcement and commercial markets, is honored to be…

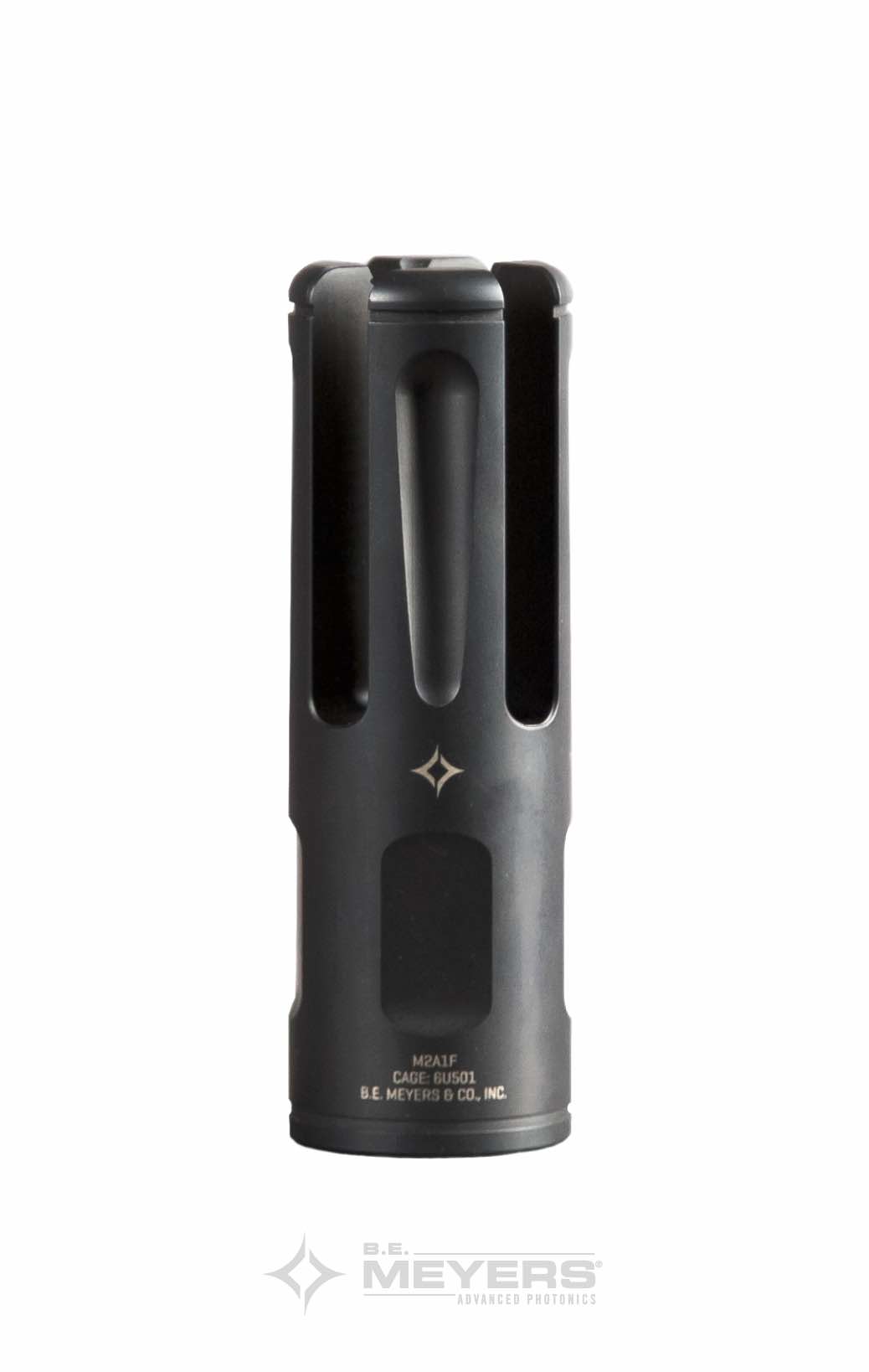

February 14, 2018 (Redmond, WA) – B.E. Meyers & Co., Inc. is pleased to announce the release of the M2A1F Flash Hider, developed in response to requests…

A federal judge on Thursday blocked a California law requiring background checks for people buying ammunition, issuing a sharply worded rebuke.

[dcs_post_top] [dcs_fancy_header bgcolor=”#ffffff” color=”#000000″ fweight=”bold”]Enter for a chance to win a Rainier Arms XTC 2.0 Compensator, Rainier Arms Force Rail 12.0, and a Rainier Arms Avalanche Charging Handle![/dcs_fancy_header]…

![[Triggrcon 2019] Brand new red dots from Sun Optics](https://un12magazine.com/wp-content/uploads/2019/08/Sun-Optics-Web-768x432.jpg)

Sun Optics announced brand new red dot optics for the AR and handgun platform that feature cast aluminum housings, clear glass, and promising durability.

In this episode we meet with ballistics expert Johann Boden from Federal Premium and CCI Speer. Johann is truly a ballistics expert and one heck of a great…

© 2026 UN12 Magazine

© 2026 UN12 Magazine

Wait! Don’t forget to

Notifications