Midwest Industries Bounty Hunter—Revolver Customization & Optimization

This past SHOT Show, Midwest Industries presented revolver enthusiasts with a new way…

This past SHOT Show, Midwest Industries presented revolver enthusiasts with a new way…

Rise Triggers’ Rev 535 Side-and-Snap AR trigger is a next-generation AR fire control…

Exploring someone else’s Everyday Carry (EDC) setup offers both insight and inspiration. While…

All shooting is a balance between speed and precision. By that I mean you can…

The Mod-Navy Qual I’ve been doing this qual (or drill, or whatever the current nom…

• Built for road trips and off-road use• Manual transmission equipped• Wrapped in MultiCam Arctic…

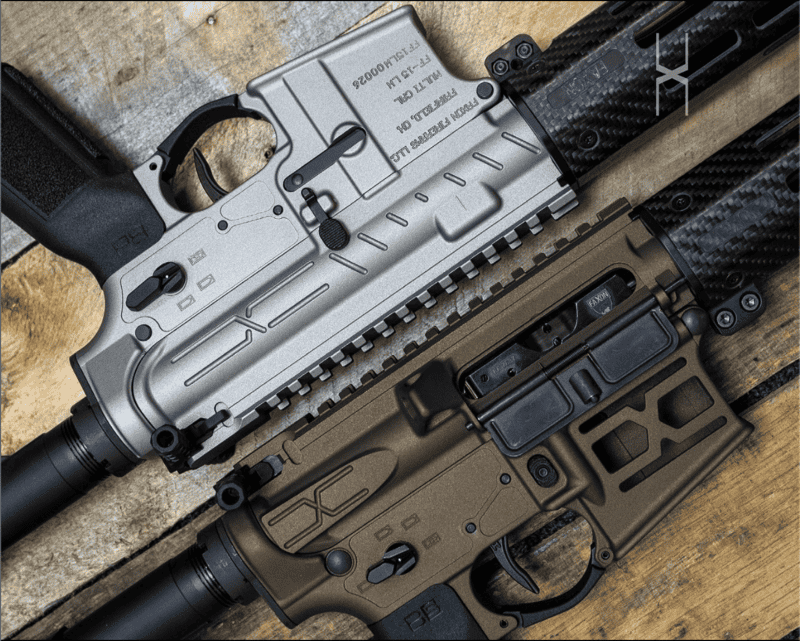

When embarking on the journey of building or upgrading an AR-15, a crucial decision lies in selecting the appropriate lower receiver. The AR-15, with its deep-rooted history spanning multiple generations, has led to an expansive range of options available in the market. These range from the traditional MIL-SPEC designs to the modern, ambidextrous, and visually appealing variants. Choosing a lower receiver involves carefully considering its manufacturing process, the materials used, and weight factors, all while keeping in mind one’s budget and functional requirements. Let’s delve into the development and nuances of AR-15 lower receivers. We’ll also highlight some notable offerings available in the market. Here’s a guide for those new to the AR-15 world, those considering an upgrade, or those simply keen on enhancing their knowledge.

A closer look at lower receiver materials reveals three primary types: cast aluminum, billet aluminum, and forged aluminum.

The manufacturing process for cast aluminum is relatively simple. It entails pouring molten aluminum into a mold. Once cooled, the resulting lower receiver undergoes final machining.

The liquid state of the aluminum during casting leads to a product with a somewhat loose crystalline structure. This method results in the least sturdy product among the three main aluminum processing techniques.

However, it’s worth mentioning that despite cast aluminum being perceived as the least strong among the trio, it offers sufficient strength for the lower receiver to operate safely and dependably. Still, when it comes to preferences, it’s often viewed as the less preferred method for crafting aluminum components.

Billet aluminum lower receivers start their journey as a solid block of aluminum, reminiscent of how a sculptor begins with a block of marble. This block is transformed into a finely crafted product through a series of precision machining operations.

Working with billet aluminum can be likened to metal sculpting, offering several advantages over the casting method. Due to their solid nature, billet lowers possess enhanced strength and showcase a superior finish.

For those aiming for a unique firearm aesthetic, billet lower receivers are ideal. Their design allows for extensive customization, enabling manufacturers to introduce distinctive features such as uniquely shaped magazine wells, integrated trigger guards, and specialized machining for weight optimization.

The creation of billet lower receivers primarily relies on CNC (Computer Numerical Control) machining. In this method, automated precision tools intricately shape a solid aluminum block, facilitating the production of detailed and highly personalized designs.

While billet lowers might carry a heftier price tag, their adaptability and visual allure make them a favorite among many. These receivers, crafted from billet aluminum and shaped by CNC machinery, are known for their crisp lines and the ability to achieve standout designs. Some aficionados even push the boundaries of design with these.

It’s important to highlight that although billet lowers are often perceived as less robust than forged lowers, this difference is typically invisible to the average user. They offer commendable durability and are unlikely to succumb to premature wear or damage. However, some uniquely designed billet lowers might have specific compatibility constraints. Therefore, ensuring their compatibility with standard MIL-SPEC components is crucial, especially if one intends to match them with a particular billet upper receiver.

Two prominent contenders emerge in the spectrum of aluminum alloys used for lower receivers: 6061-T6 and 7075-T6. The primary distinction between these two lies in their strength and resistance to corrosion.

7075-T6 is characterized by its remarkable strength, surpassing 6061-T6 by almost double in this aspect. This difference in strength is reflected in the price, with 7075-T6 generally being the pricier of the two. However, it’s essential to recognize that 6061-T6 offers enhanced corrosion resistance compared to 7075-T6. While this resistance can be a significant advantage, its relevance might vary based on whether the receiver retains its natural aluminum appearance or undergoes specific finishing processes.

When planning your firearm assembly, balancing the need for superior strength against budgetary constraints is wise. The gap between 7075 and 6061 is relatively narrow in the current landscape. Nonetheless, many opt for the added assurance of 7075-T6’s robustness, making it a favored choice. Notably, 7075-T6 aluminum is frequently used in aerospace industries due to its outstanding strength-to-weight ratio and resilience, further emphasizing its reputation for dependability and longevity.

Are you embarking on your first firearm project? You’ll likely encounter two primary options for lower receivers: stripped and complete. The inevitable question is, “What differentiates the two, and which is the better fit for me?” Let’s break down the distinctions to guide your decision.

At first glance, stripped lower receivers might seem incomplete. They lack several vital components required for a fully operational lower receiver, such as the trigger, buffer tube, buffer, and stock.

So, why might one opt for a stripped lower receiver, given these omissions?

However, stripped lowers come with challenges:

Conversely, complete lower receivers are ready to roll outfitted with all essential components. With a complete lower in hand, pairing it with an upper receiver is all that stands between you and a fully operational rifle.

Benefits of a complete lower receiver include:

Yet, complete lowers have their limitations:

The decision between stripped and complete lower receivers boils down to individual preferences, expertise, and the desired balance between customization and convenience in your firearm project.

In the vast landscape of AR lower receivers, Faxon‘s products have garnered attention for their quality and design. Let’s delve into one of their standout offerings.

The Faxon HyperLite AR-15 Receiver Kit is a notable choice for those aiming for a lightweight yet robust build. Building upon the foundation of their acclaimed forged receiver set, this kit emphasizes a balance between aesthetics, functionality, and durability while significantly reducing weight.

Key Features:

The kit is also available in OD Green Cerakote, Titanium Cerakote, and Midnight Bronze for those interested in color variations. The Faxon HyperLite AR-15 Receiver Kit encapsulates a harmonious blend of design, functionality, and innovation, making it a worthy consideration for discerning builders.

The Faxon Billet AR-10 Receiver Set stands as a testament to meticulous engineering and an unwavering commitment to quality. This set is tailored for discerning firearm enthusiasts seeking a comprehensive upgrade for their AR-10 rifle.

Material and Durability:

This set’s stripped upper and lower receivers are crafted from high-grade 7075-T6 aluminum billet. This choice of material ensures a balance between lightweight design and robust strength, making the set ideal for enduring rigorous use while maintaining reliability.

Design Highlights:

Faxon’s dedication to superior design is evident in several unique features:

Upper Receiver Specifics:

Lower Receiver Details:

The Faxon AR-15 Builder Set in FDE (Flat Dark Earth) is a culmination of precision engineering and innovative design. With a custom Cerakote finish, this set offers both functionality and a distinctive aesthetic.

Key Features:

This builder set showcases Faxon’s commitment to craftsmanship and design. A custom Cerakote finish in Combat Grey offers a blend of performance and aesthetics.

Key Features:

*Also available in Charcoal Green.

Choosing the right lower receiver balances objectives, budget, and familiarity with AR-15 mechanics.

Quality Over Features: While additional features can be appealing, the cornerstone of a reliable AR-15 build is a quality lower.

• Based on SIG Sauer MCX Virtus• Outfitted for night vision/low-light use• Chambered in 5.56x45mm In April 2022, the U.S. Army selected the SIG Sauer XM7 as the replacement…

Some people love them, some people not so much (count us among the lovers). But whatever your feeling on the subject, it can’t really be said that Glock…

Polymer Ammunition represents a significant development in the world of firearms, and HOP Munitions is a notable player in this field.

Whatever else happened in 2020, it was a seminal year for firearms sales. Here are the ten top-selling semiautomatic pistols (new, as opposed to used or pre-owned) according…

• Rolex Milgauss-themed Glock• Based on a Glock 19 Gen3• Custom Cerakoted & stippled When it comes to timepieces, there may be no other brand that can top…

Faxon Firearms, a leader in the firearms industry, is proud to announce the release of its new EXOS Pistol Compensator, designed to significantly enhance the performance of the…

© 2026 UN12 Magazine

© 2026 UN12 Magazine

Wait! Don’t forget to