SIG Sauer P211 GT4 & GT5—The Sports Cars of SAO Pistols?

In a world where shooters can’t get enough of 2011-style pistols, SIG introduced…

In a world where shooters can’t get enough of 2011-style pistols, SIG introduced…

The Folding Defensive Platform from Zev Technologies—FDP for short—is a new take on…

The GSR-05 Slide Racker is TangoDown’s latest addition to its Vickers Tactical lineup….

All shooting is a balance between speed and precision. By that I mean you can…

The Mod-Navy Qual I’ve been doing this qual (or drill, or whatever the current nom…

• Built for road trips and off-road use• Manual transmission equipped• Wrapped in MultiCam Arctic…

To understand how the mind of Bill Geissele works, you truly need to be in front of him. I’ve had to opportunity to meet him a couple of times, most recently at his Geissele Automatics office in North Wales, Pennsylvania. His vast knowledge of weapons is truly something that is amazing. An encyclopedic reference of all things weapons is engrained in his mind and fortunately for us, he is able to translate that into the weapons and weapons parts his company and team manufacturers.

Growing up in New Jersey, Bill started shooting at a young age with his siblings and his father. What he also did at a young age was start to work, and he started working to save money for one of his first weapons, a side-by-side shotgun that he bought at a local gun store. Continuing to work and save money, Bill was able to save for reloading equipment, as he and his brother shot almost every weekend and he needed to feed his habit affordably while shooting at a local area frequented near his childhood home.

At 15 years old, Bill found himself asking a local neighbor if he had any work for him in his machine shop. This was a one-man machine shop and Bill was able to begin working with a man who he still holds in high regard as someone who gave him an opportunity and taught him many lessons that he remembers to this day. Working in his shop, Bill learned cleanliness, how to set up machines properly before working on them, how to read drawings and a myriad of other machinists ways of working correctly with tools and dies. During this time in his life, Bill also worked on another passion of his, motorcycles. He learned what it was like to turn a wrench and figure out problems with a toolbox and a mind that would help him figure out how to keep engines running.

Enjoying what he did as a machinist, Bill found himself finishing high school and needing another job. He loved what he did as a machinist and this propelled him onto a few different paths in engineering. Shortly after high school and enrolling in a community college, Bill found himself working in different types of mines and on their massive pieces of equipment.

Bill was single at the time and was able to work all over the world at different mining operations with sometimes just a day’s notice. He worked on machines that were as large as four and five story buildings, keeping them running and also diagnosing different problems as they arose. From mines in South America, to countries on the Pacific Rim, to some of the coldest places in Russia, Bill’s passport was stamped at all of these locations.

While he was working for the mining operations, Bill realized that he wanted to finish his schooling and began working to save money so he could finally finish his college education. After a rather long stint in Russia, he came back to the United States and back to New Jersey to finish his degree in engineering. With more than a decade of real world experience, Bill flew through the engineering program at Rutgers in New Jersey. Having been on the ground and worked as an engineer and a machinist for mining operations, Bill took to finishing his education with ease that perhaps other students with no real world experience could draw upon.

Once he was done with his education Bill started working for the railways. Within a matter of months he had engineered a few items that had been plaguing the industry for more than two decades. Again, his sense of real world working and his ability to bring numerous different visions into a new arena allowed for him to see things differently. He and his mind were not stuck in the proverbial box. Again, having had the opportunity to work throughout quite a few different areas in engineering and mechanics allowed Bill to think differently then some of his colleagues.

While working in the railway system, Bill realized a few things. He realized that he wanted to start a family and he also understood that he had to be a good provider to a family if he was going to start one. It was about that time in the early 2000’s that he began working on the idea of improving triggers. If he were able to build triggers and make extra money as a result of this business, this would equate to more earnings to support a family.

Bill was a weekend match shooter and shot AR-15s in sanctioned matches during his off time. In wanting to keep his scores up towards the top, Bill realized that the trigger was one thing that was lacking in shooting and keeping high scores and keeping rounds in the X ring. There were match triggers available at the time, but nothing that was to his liking. Being the engineer and having a mechanics mind, the idea for his trigger came to him late one night while reading in bed.

Little by little, Bill worked on a two-stage trigger system that would allow him a consistent trigger press. With his drawings and connections with other machinists who helped him make parts, Bill began building triggers in the basement of his Pennsylvania row house. Within a couple of months, Bill had his first production High Speed National Match trigger and in 2004 Geissele Automatics was born.

Going to matches at the time of his trigger launch, Bill began to gain some attention both on the shooting line and off. Of the people who began to show interest in the new Geissele Automatics trigger were some shooters with the Department of Defense. While at a match one weekend, Bill was asked to show his trigger to a team captain of one of the DOD’s shooting team. With his weapon in hand Bill introduced himself and began to discuss his trigger system with the team captain. Liking the feel of his trigger the team captain asked Bill one question, “What hammer spring are you using?” Bill replied with what he was using, “An A1 hammer spring.” This is what the captain wanted to hear and with that conversation a friendship began with Bill and the DOD.

From the early start of Geissele Automatics in 2004, Bill kept making triggers in his basement while still working as an engineer. With demand for his triggers growing, other triggers coming out and working on items that were requested by DOD units, Bill quit his engineering job and moved Geissele Automatics into a shop in 2008.

In the past decade Geissele Automatics has been tasked to come up with many items for a myriad of weapon systems. Most notably is the AR-15 or M16 family of weapons. If you need to dress up your weapon, you can pretty much change out anything and everything on any stock weapon and exchange everything out with a Geissele product. Their triggers are outstanding and are in use within the Special Forces community on every carbine that is found in the field. That is quite a testament to the engineering and the mind of Bill Geissele and the entire crew at Geissele Automatics.

Bill has come up with some of the most innovative and accurate additions to different weapon systems used throughout the world. He and his crew do this with a great amount of input from people with boots on the ground and in places all throughout the globe. The crew at Geissele Automatics has such a great relationship with units within the Department of Defense that they often come up with projects together.

Most recently was Project Joy, a semi-automatic carbine in .260 Remington that is used with unit in the Special Operations community. Additionally, I cannot complete this article without mentioning the Upper Receiver Group – Improved or URGI. This Upper is the first upper to see a mid length gas system and a cold hammer forged barrel used widely with Special Operations of the Department of Defense.

Bill Geissele will be the first to tell you that Geissele Automatics is not about Bill himself. Rather it is all about the team at Geissele. This business would not be Geissele Automatics without the talented people that he has pulled from Pennsylvania and the area around North Wales to truly make up the Geissele Automatic’s team.

For more about Bill Geissele and his products, visit: geissele.com.

Geissele’s Upper Receiver Group – Improved (URG-I)

In 2017 the Naval Surface Warfare Center at Crane, Indiana conducted a rather lengthy test on Mid-length versus Carbine-length gas systems on 14.5” Upper Receiver Groups. Their test report, all sixty-six pages, are now available to readers outside the Department of Defense. In this in-depth report the research team, which consisted of the organizer, Project leads, engineers and managers at Crane, they set out with the intent to examine changes in reliability, precision, bolt speed and barrel erosion between the two different length systems. The barrels used during this test of the M4A1 Upper were Daniel Defense Cold Hammer Forged (CHF) barrels.

The testing consisted of taking six uppers and outfitting three with a mid-length gas system and three with a carbine-length gas system and putting them through a 12,600 round test. Testing was done with suppressors and without, measurements of critical areas were taken at specific intervals, malfunctions were tracked and at the end of the testing it was determined that a 14.5” CHF barrel and a mid-length gas system would be best suited for USASOC. The report is long, but contains some great information, but I’d rather not regurgitate it all in this piece.

With this information being sent out to defense suppliers, Geissele Automatics saw an opportunity to add their name to a list of potential suppliers for the new Upper Receiver Group. Right away Bill Geissele and his team at the Geissele plant set out to put their best efforts forward to supply USASOC and the boots on the ground the best upper possible to add to the M4A1’s that were fatigued. Within short order Geissele had come up with their recipe, the Upper Receiver Group – Improved (URG-I). They submitted the following items to Crane, who then builds the uppers for USASOC.

The URG-I starts with their MK16 13.5” SOCOM Modular Handguard, which is coated in their Desert Dirt Color. The Geissele Super Select Fire (SSF) Trigger Assembly, High Speed Selector, Airborne Charging Handle and Maritime Bolt Catch. These items are sent to Crane where they see final assembly.

For those who want to shoot an upper as close to the military as you can get, Geissele just launched and released their URG-I Complete, Near Clone, 14.5” upper. To make it even closer to those uppers found at USASOC, Geissele partnered with Surefire and they made a deal to supply their four-pronged WARCOMP to the completed URG-I! This is the first time the four-pronged WARCOMP has been sold to someone other than the DOD. How’s that for authentic?

I’ve been shooting the URG-I for the past few months, complete with a Surefire SOCOM Suppressor and I can tell you the function is flawless, accuracy is better than I can hold and recoil is negligible. The slimline profile of the MK16 rail fits easily in my hands with no excess real estate and the M-LOK rail system is strong. Flatness up top is kept absolute, so mating devices to this weapon is superb.

Text by Jason David and images by Michael Grey & provided by Geissele.

Based in Petaluma, California, Begg Knives consists of a highly skilled group of craftsmen who specialize in creating limited runs of knives that combine exotic materials, modern alloys,…

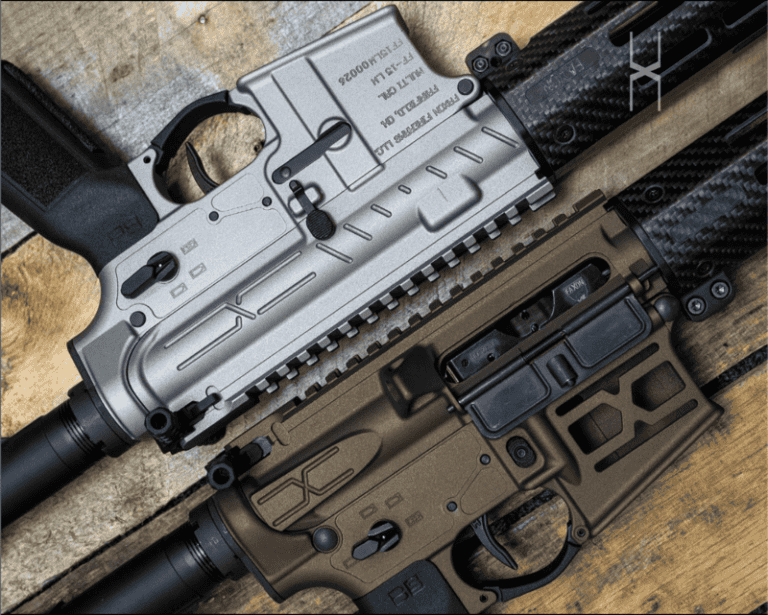

Let’s delve into the development and nuances of AR-15 lower receivers. We’ll also highlight some notable offerings available in the market.

Being a complex system of interrelated moving parts, a firearm is not so different from an automobile. Anyone who has ever experimented with improving performance in a car,…

“Simple is better.” That’s one of the mantras that Eric Valdes, founder of Wetwerks USA, keeps in mind when he’s designing his custom pistol slide cuts. Focusing exclusively…

Faxon and Refactor teamed up again to create another guide to explore the firearms frontiers for you. They’ve pooled their expertise and research together to talk to you…

© 2026 UN12 Magazine

© 2026 UN12 Magazine

Wait! Don’t forget to